DMP Planetary Mixer

Features

1.DMP Planetary Mixer is suitable for mixing all high-quality concrete (dry hard, semi dry hard, and plastic concrete) and achieving high uniformity in a short period of time. It can also be used in industries such as glass, ceramics, and refractory materials.

2.The specially developed gearbox can effectively distribute power balance to various mixing devices, ensuring low-noise transportation even under harsh production conditions. At the same time, it saves more space, and compared with traditional gearboxes, the maintenance space of the mixer can be increased by 30%.

3.Elastic couplings and hydraulic couplings (optional) can effectively protect the transmission system from the impact of overload.

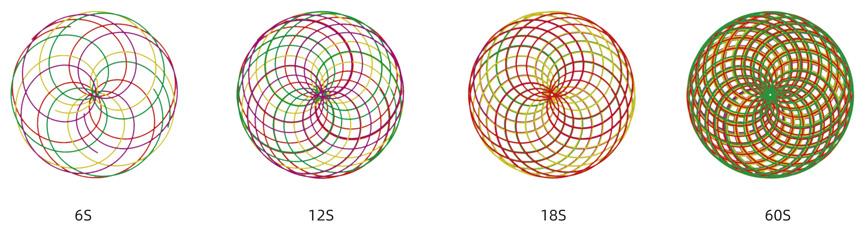

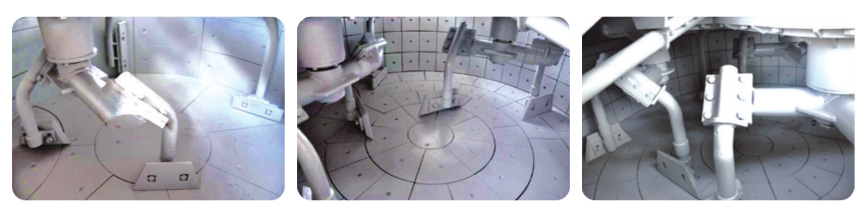

Mixing Locus Diagrams

This diagrams show the perfect mixing action of the DEX planetary mixer from 6 to 60 seconds after material added. Note that the floor is completely swept by the mixing stars' action every 4 revolutions (6 seconds) and that each zone is covered at regular intervals in time.

DMP Planetary Mixer

|  |

| Reduction Gearbox | Maintenance Access |

The gearbox unit, specially designed for a balanced distribution of power to the various mixing device, ensures a high efficiency and low-noise rotation. | Large access facility is for easy maintenance and cleaning. |

|  |

| Hydraulic Unit | Discharging Door |

Hydraulic unit equipped with manual pump allows the door be opened in case of electric failure. | The discharging door is equipped with limit switches, which can be opened at any angle.Maximum three discharging doors are available. |

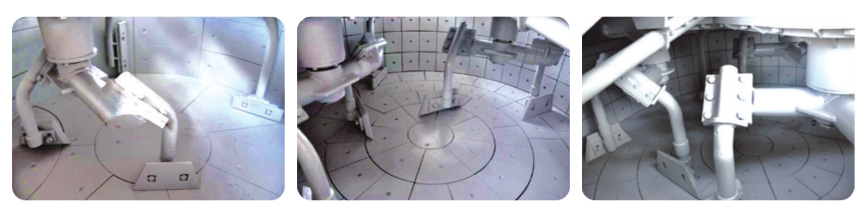

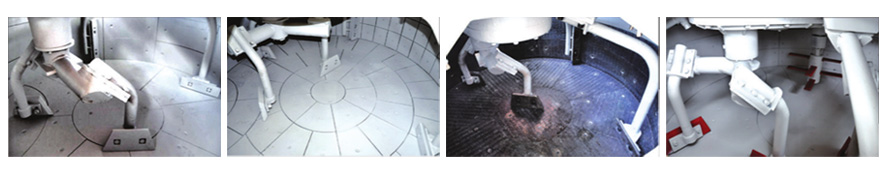

Mixing Device

Special designed mixing facility

make the mixing faster and more

homogeneous, no material heaped.

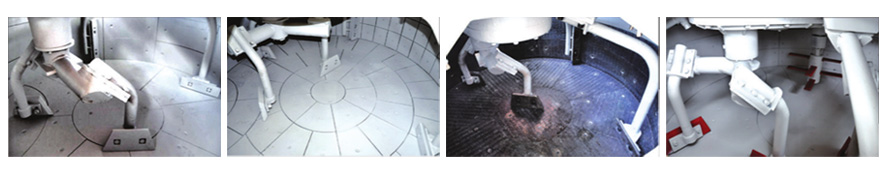

Various arrangement and materials of the mixing device

Various arrangement and materials of the mixing device

Optional items

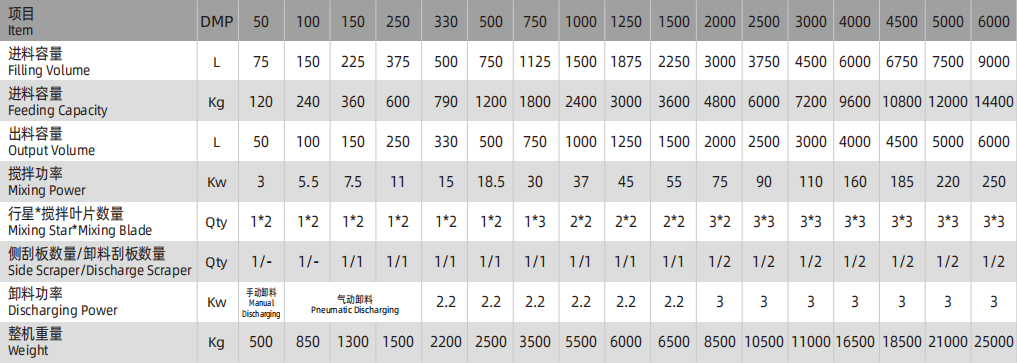

Specifications